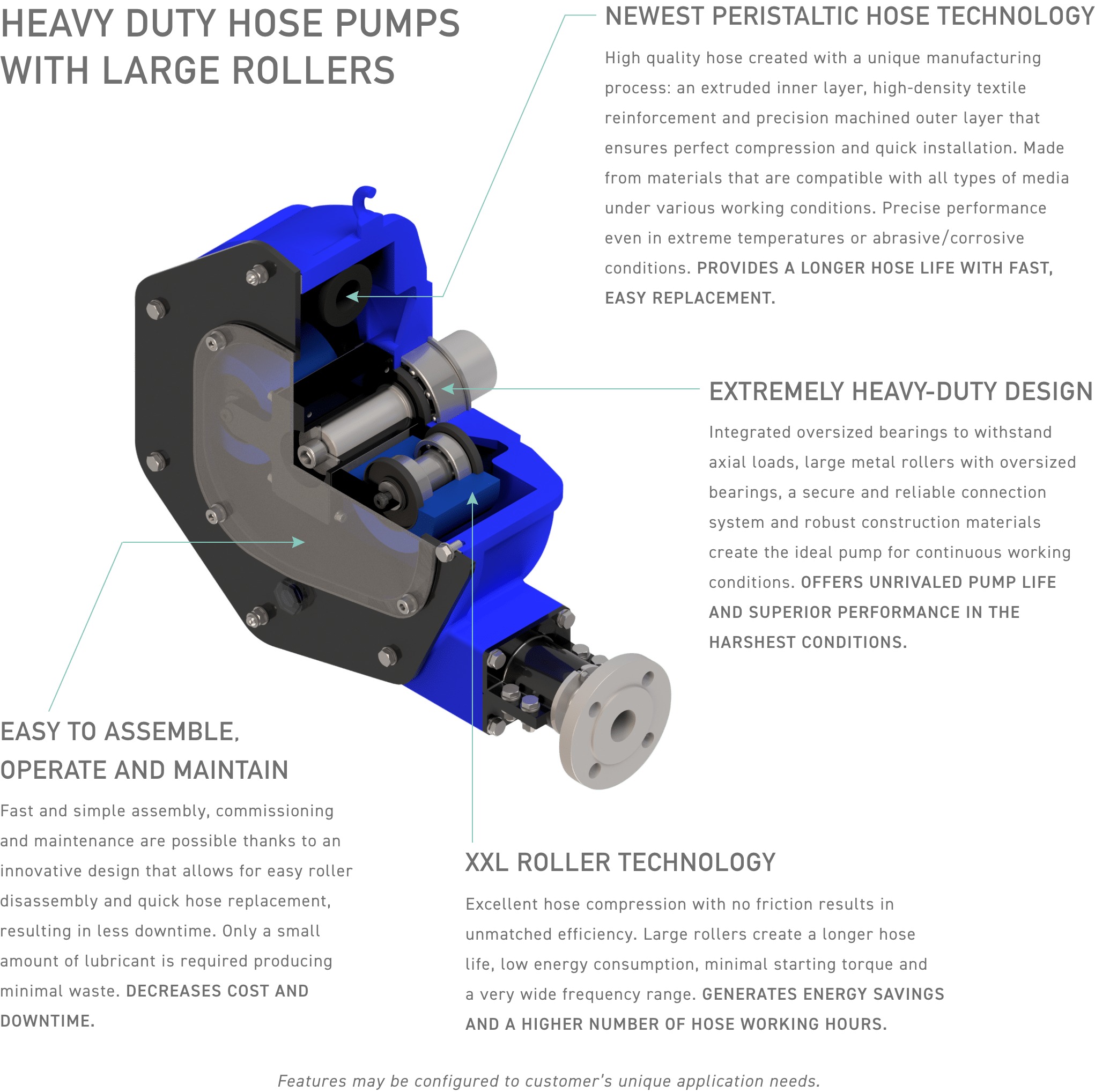

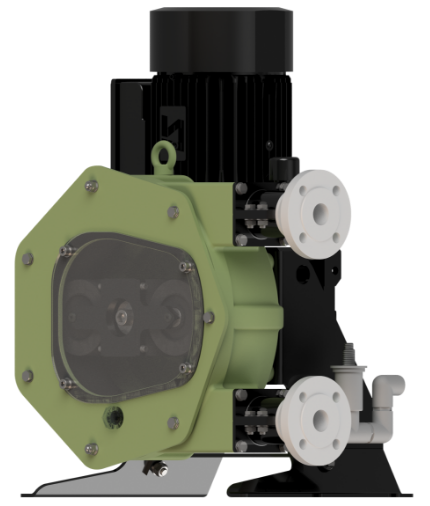

Heavy-duty hose pumps with large rollers

Newest peristaltic hose technology

High quality hose created with a unique manufacturing process: an extruded inner layer, high-density textile reinforcement and precision machined outer layer that ensures perfect compression and quick installation. Made from materials that are compatible with all types of media under various working conditions. Precise performance even in extreme temperatures or abrasive/corrosive conditions. Provides a longer hose life with fast, easy replacement.

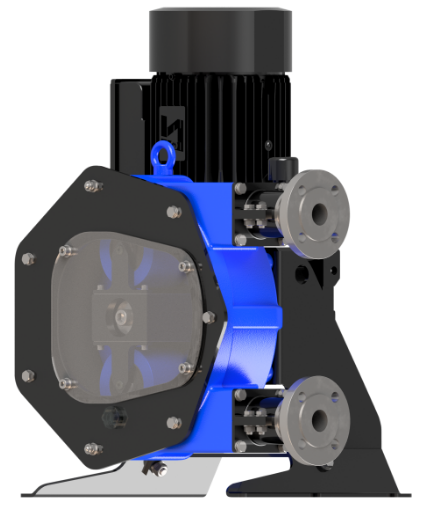

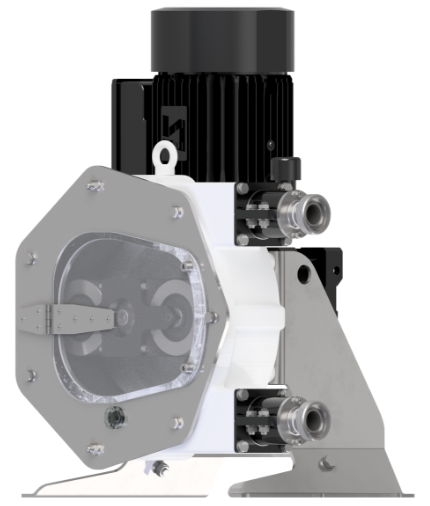

Extremely heavy-duty design

Integrated oversized bearings to withstand axial loads, large metal rollers with oversized bearings, a secure and reliable connection system and robust construction materials create the ideal pump for continuous working conditions. Offers unrivaled pump life and superior performance in the harshest conditions.

Easy to assemble, operate and maintain

Fast and simple assembly, commissioning and maintenance. An innovative pump design allows for easy roller disassembly and quick hose replacement, resulting in less downtime. Maintenance-free pump with lubricated-for-life system requires only a small amount of lubricant, producing minimal waste. Decreases cost and downtime.

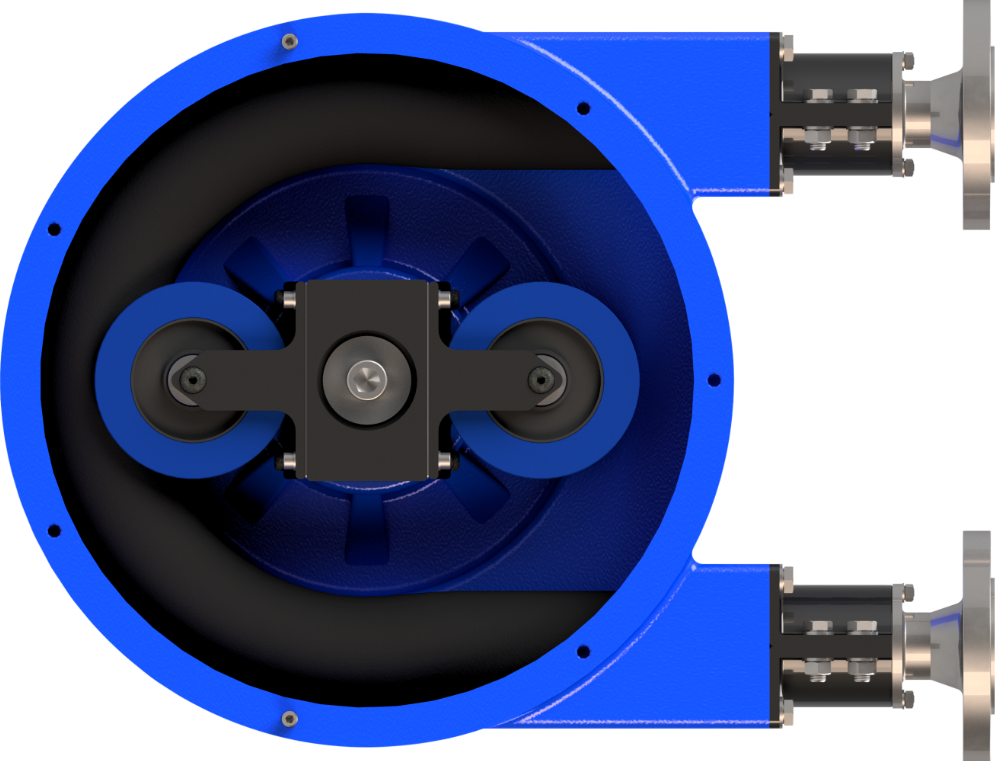

XXL roller technology

Excellent hose compression with no friction results in unmatched efficiency. Large rollers create a longer hose life, low energy consumption, minimal starting torque and a very wide frequency range. Generates energy savings and a higher number of hose working hours.