The Granzow food-grade peristaltic pump is an ideal solution for the unique, sanitary needs of food and beverage producers. A variety of features ease and accelerate clean-in-place (CIP) processes. The hose and fittings are the only components that come in contact with the flowing media and the rolling action of the pump creates a wave of liquid that carries solids through the pump without damaging them.

Key Benefits

- Easy to assemble, operate and maintain

- NBR/Buna-N FDA compliant hose

- Sanitary 316 stainless steel (SS) tri-clamp connections

- Hinged front cover for easy cleaning

- Roller assembly dismantles with ease

- Pumps in both directions to effectively flush media

- Gentle pumping with maximum efficiency

- Requires significantly less lubricant compared to shoe pumps

- Full control of dosing with ±1% accuracy

Common Applications

- Viscous juices, sauces and syrups

- Vegetable or fruit skins

- Media with solid pieces in the mixture

- Yeast and diatomaceous earth for brewing beer

- Wine

- Dough and batters

- Casseroles, stews, and meat fillings

- Pie fillings

- Pet food

- Condiments and spreads

- Sweeteners and frostings

- Flavorings, colorings and additives

- Chemical dosing and waste transfer

Perfect for dosing liquids, transferring highly viscous media or gently pumping food slurries with solid content

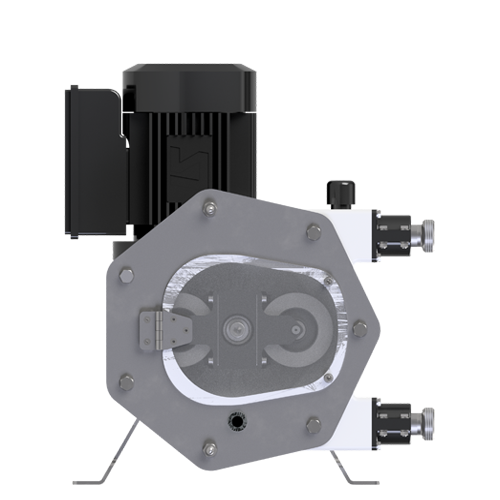

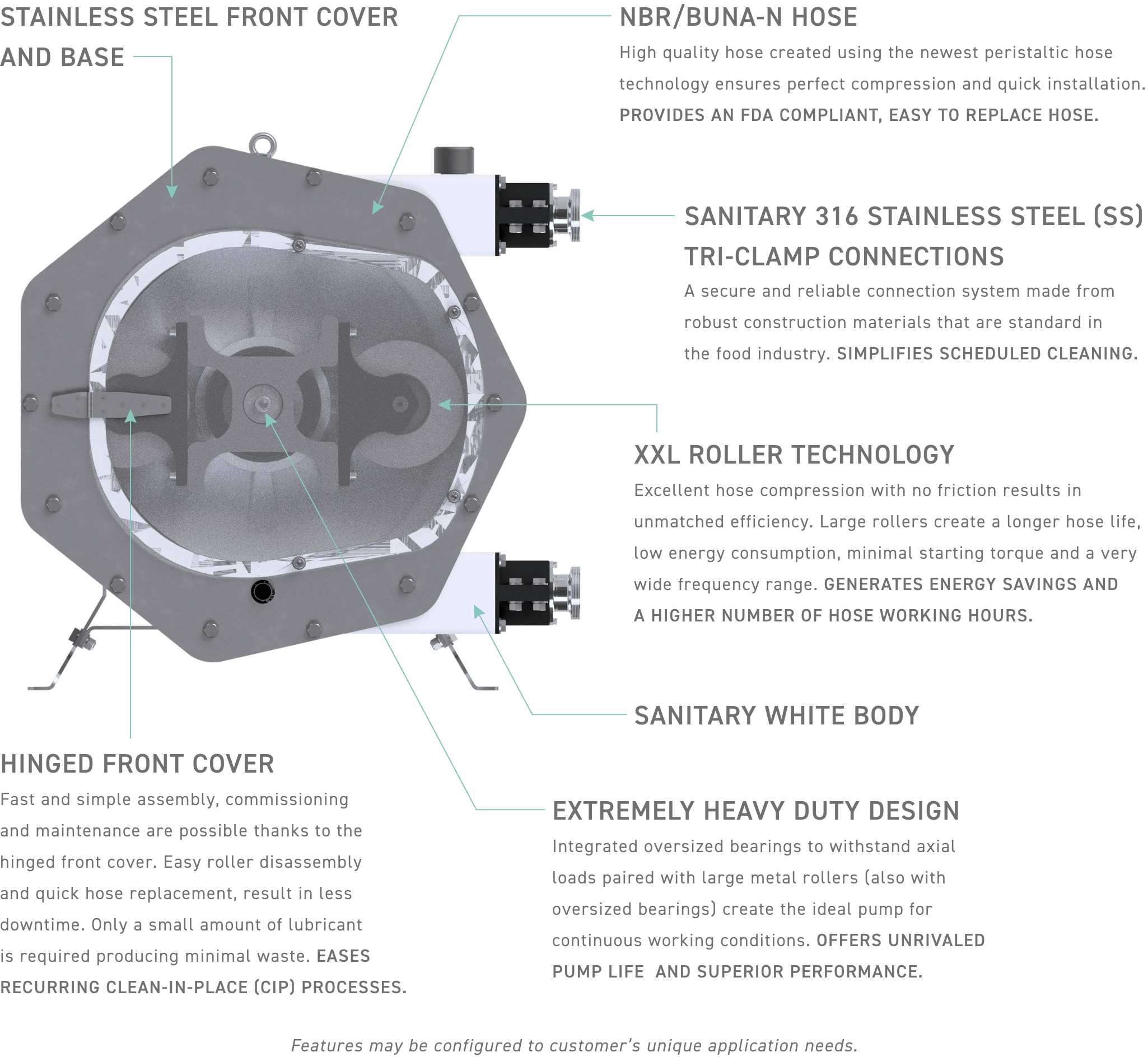

Stainless steel front cover and base

NBR/BUNA-N hose

High quality hose created using the newest peristaltic hose technology ensures perfect compression and quick installation. Provides an FDA-compliant, easy-to-replace hose.

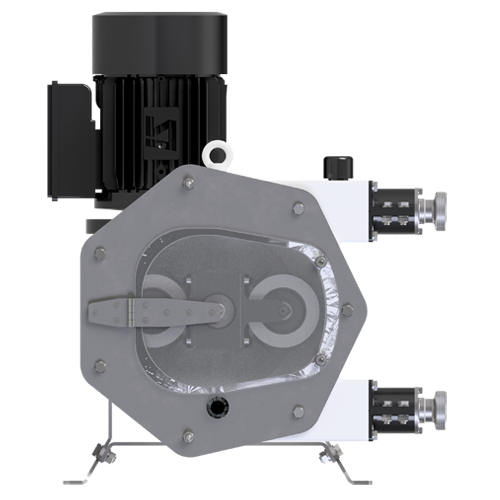

Sanitary 316 stainless steel (SS) tri-clamp connections

A secure and reliable connection system made from robust construction materials that are standard in the food industry. Simplifies scheduled cleaning.

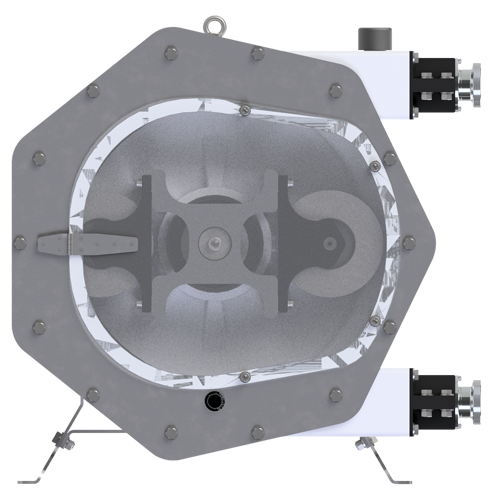

XXL roller technology

Excellent hose compression with no friction results in unmatched efficiency. Large rollers create a longer hose life, low energy consumption, minimal starting torque and a very wide frequency range. Generates energy savings and a higher number of hose working hours.

Sanitary white body

Extremely heavy-duty design

Integrated oversized bearings to withstand axial loads paired with large metal rollers (also with oversized bearings) create the ideal pump for continuous working conditions. Offers unrivaled pump life and superior performance.

Hinged front cover

Fast and simple assembly, commissioning and maintenance are possible thanks to the hinged front cover. Easy roller disassembly and quick hose replacement, result in less downtime. Only a small amount of lubricant is required producing minimal waste. Eases recurring clean-in-place (CIP) processes.