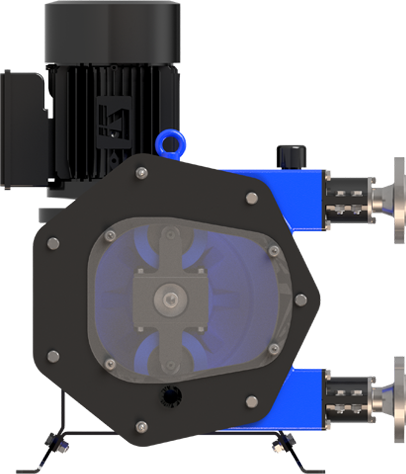

Industrial version

Well suited for a wide range of uses, including transferring media that is highly viscous or contains solids

Granzow's peristaltic pumps are the perfect solution for demanding applications in paper manufacturing processes, such as transferring high-density pulps, chemicals or wastewater with fiber residue. Our pumps completely contain the pumped fluid in the hose without the use of vales or mechanical seals. A superior design enables the easy, accurate and repeatable transfer of high-density pulps as well as other hazardous or abrasive materials.

Well suited for a wide range of uses, including transferring media that is highly viscous or contains solids

A perfect choice for dosing highly corrosive products such as hydrochloric acid or urea

Excellent choice for handling a wide range of paper applications, including viscous slurries, abrasive media and the transfer of fluids and shear-sensitive materials.

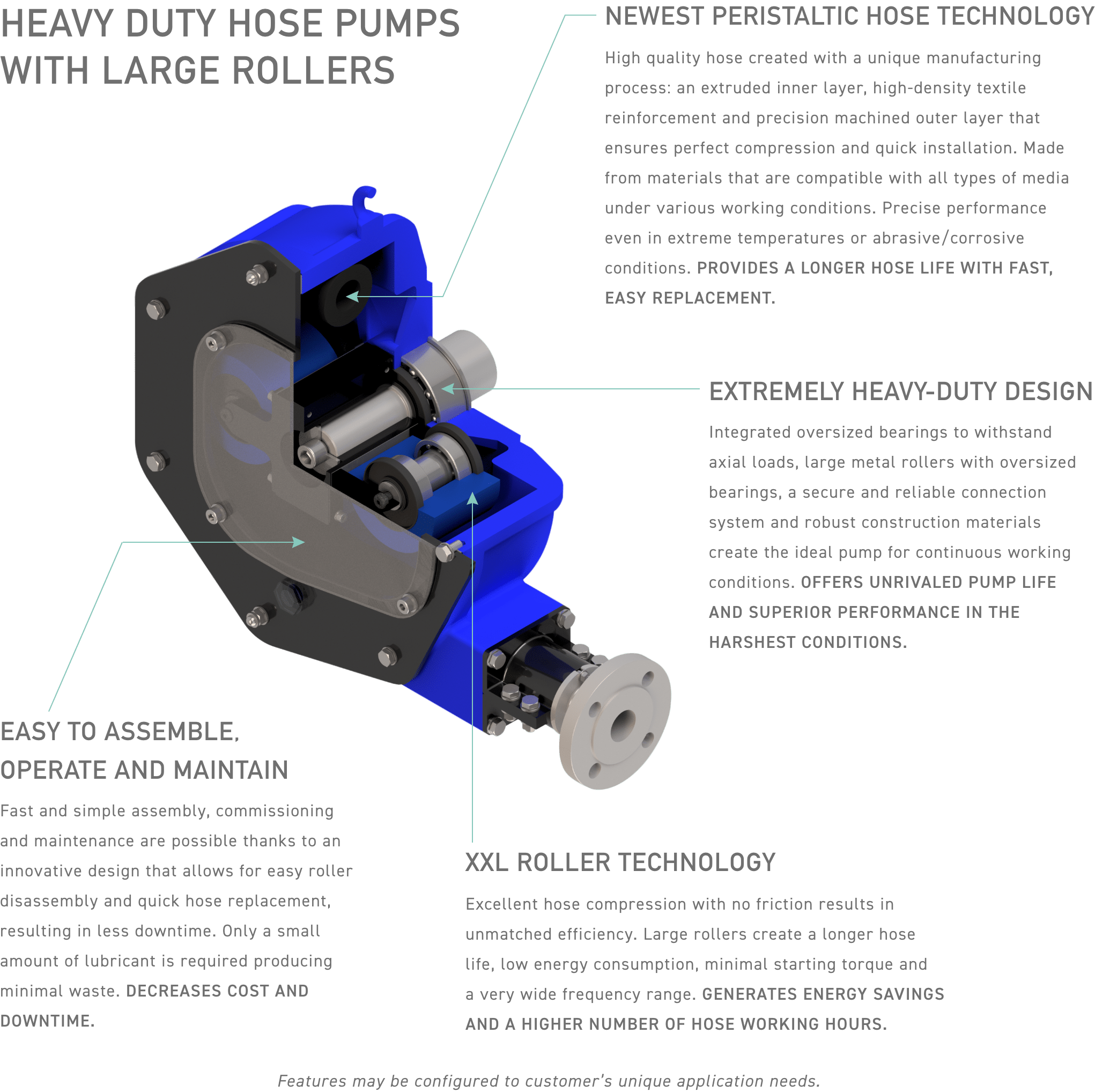

High quality hose created with a unique manufacturing process: an extruded inner layer, high-density textile reinforcement and precision machined outer layer that ensures perfect compression and quick installation. Made from materials that are compatible with all types of media under various working conditions. Precise performance even in extreme temperatures or abrasive/ corrosive conditions. Provides a longer hose life with fast, easy replacement.

Integrated oversized bearings to withstand axial loads, large metal rollers with oversized bearings, a secure and reliable connection system and robust construction materials create the ideal pump for continuous working conditions. Offers unrivaled pump life and superior performance in the harshest conditions.

Excellent hose compression with no friction results in unmatched efficiency. Large rollers create a longer hose life, low energy consumption, minimal starting torque and a very wide frequency range. Generates energy savings and a higher number of hose working hours.

Fast and simple assembly, commissioning and maintenance are possible thanks to an innovative design that allows for easy roller disassembly and quick hose replacement, resulting in less downtime. Only a small amount of lubricant is required producing minimal waste. Decreases cost and downtime.

Features may be configured to customer's unique application needs.