Easy-to-maintain pumps that accurately dose corrosive media

The chemical-version peristaltic hose pumps are an anti-corrosive and unrivaled solution for dosing or transferring acids and other abrasive products.

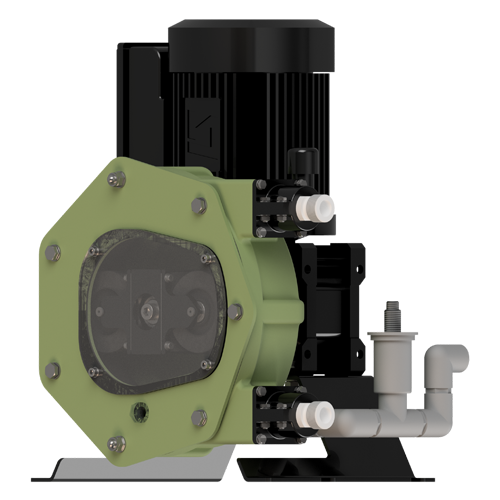

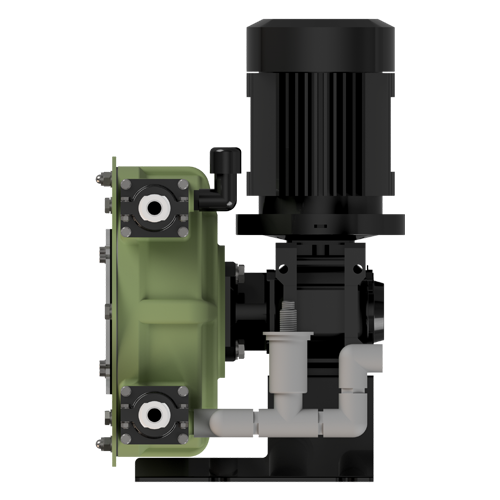

- State-of-the-art hose available in EPDM rubber or Hypalon rubber (CSM)

- Tefzel-coated front cover and housing

- Polypropylene or PVDF connections

- Hose leakage sensor

- Pump and roller lip seals in EPDM rubber

- Corrosion-resistant rollers

- Drainage system

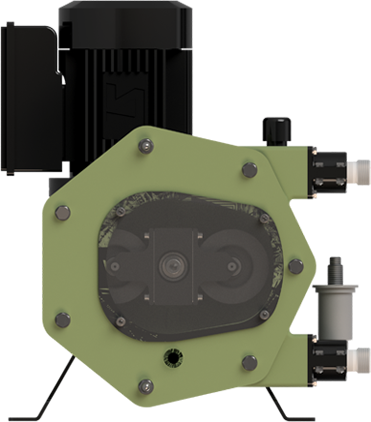

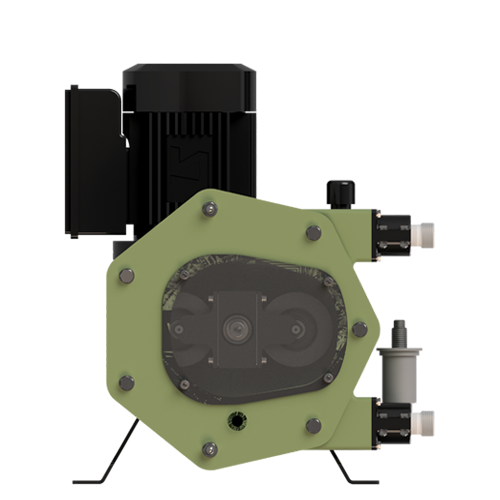

Model C12 is a small but heavy-duty pump with XXL rollers. The bearings installed between the rotor and the gear reducer fully absorb axial loads, freeing the reducer from fatigue and thus maximizing service life. The precision of the compression components, the peristaltic hose's unique manufacturing process, and the quality of materials result in a pump that is unique to the market and unmatched in quality.

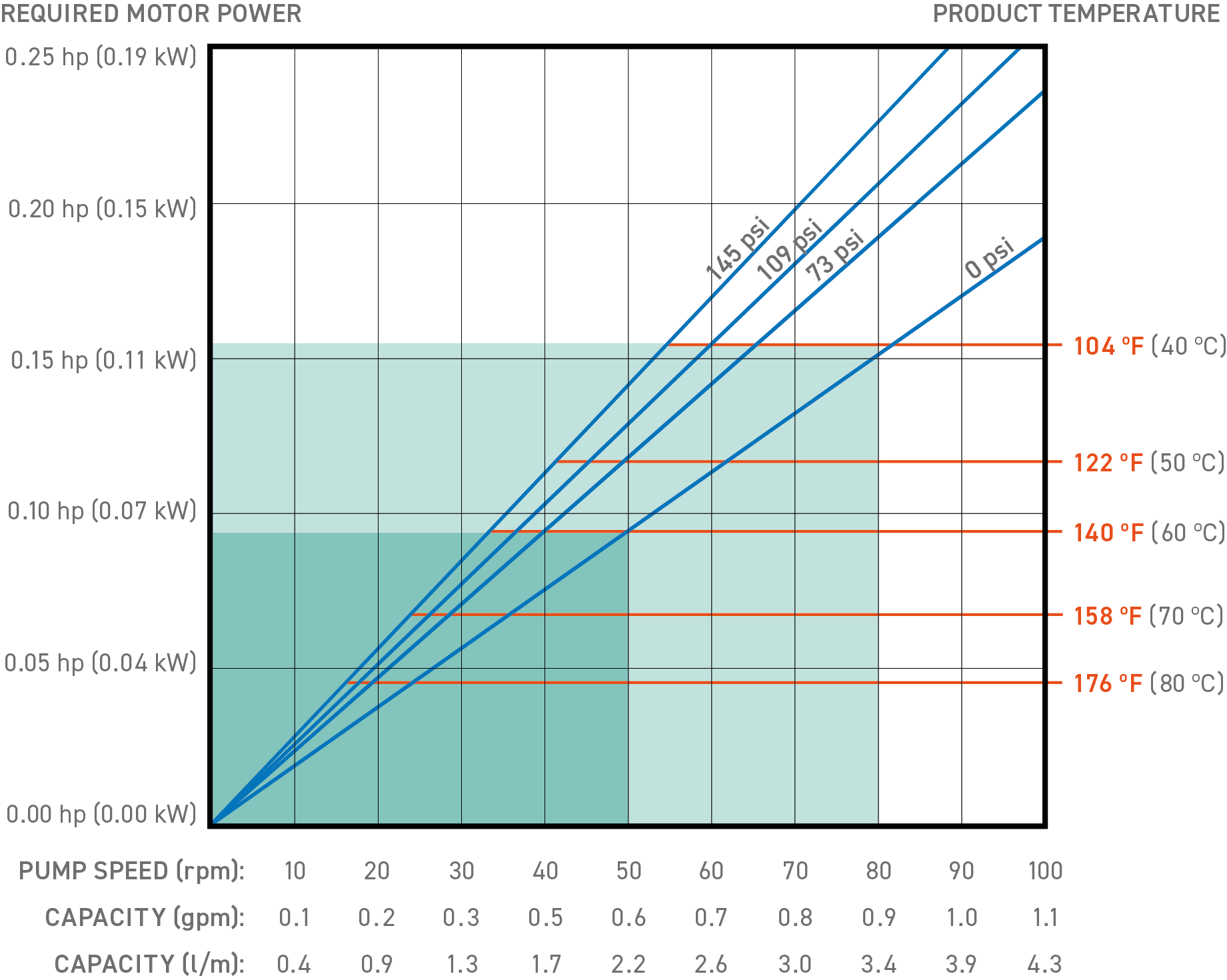

Model C12 is capable of pumping up to 0.75 gpm and handling discharge pressures of up to 145 psi. This robust pump with a compact, vertical design is ideal for transferring any type of abrasive, corrosive, viscous, or delicate media.

This low-flow-rate pump is perfect for dosing chemicals, additives, lime milk, activated carbon, and polymers due to the accurate flow-rate control. Easy to assemble, operate, and maintain; the C12 peristaltic hose pump will maximize efficiency while minimizing downtime and maintenance costs.

Continue reading

Datasheet

Build your custom peristaltic pump with our free and easy tool:

C12 Technical Specifications

Dimensions

*Depending on the driver, dimensions could change.

Build your custom peristaltic pump with our free and easy tool: