Granzow's pumps boast unrivalled performance in tough and uncompromising environments that are common with the ceramics industry. Highly abrasive fluids that contain solid content can be easily and consistently transferred with minimal maintenance and product waste. Our pumps contain no mechanical seals or valves and are constructed with premium materials that feature the newest peristaltic hose technology.

Key Benefits

- Constructed with durable materials to easily transfer abrasive products

- Short filter times due to the pump's regular flow and prevention of air pockets

- Heavy duty design allows 24/7 continuous use

- Easy to assemble, operate and maintain

- No valves, seals, or glands to lead, clog or replace since no mechanical parts come into contact with the pumped media other than the hose and connections

- Operates without damage if supply lines run dry

- Requires significantly less lubricant compared to shoe pumps

- Low ownership costs due to the pump's long life and easily changeable wear resistant hoses

Common Applications

- Pumping abrasive slurries that contain suspended particles and ceramic waste

- Dosing abrasive products like barium carbonate and potassium permanganate

- Transferring slip at high temperatures and gravity

- Mill loading and unloading operations

- Transporting content among recycling tanks, vibrating screens, feed tanks for spray dryers and sewage treatment workshops

- Dosing mortars and glazes at high pressures

Perfect for dosing highly corrosive products or transferring viscous sludges, slurries and high-solids media.

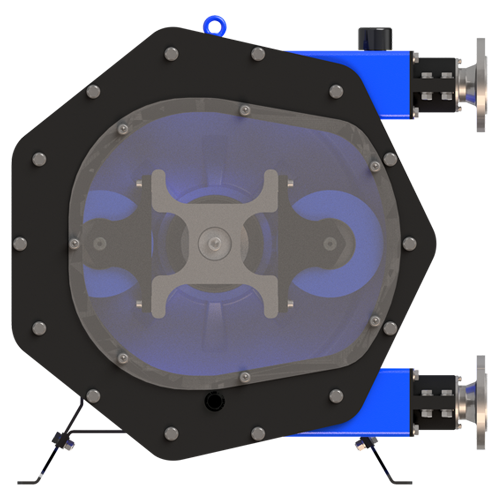

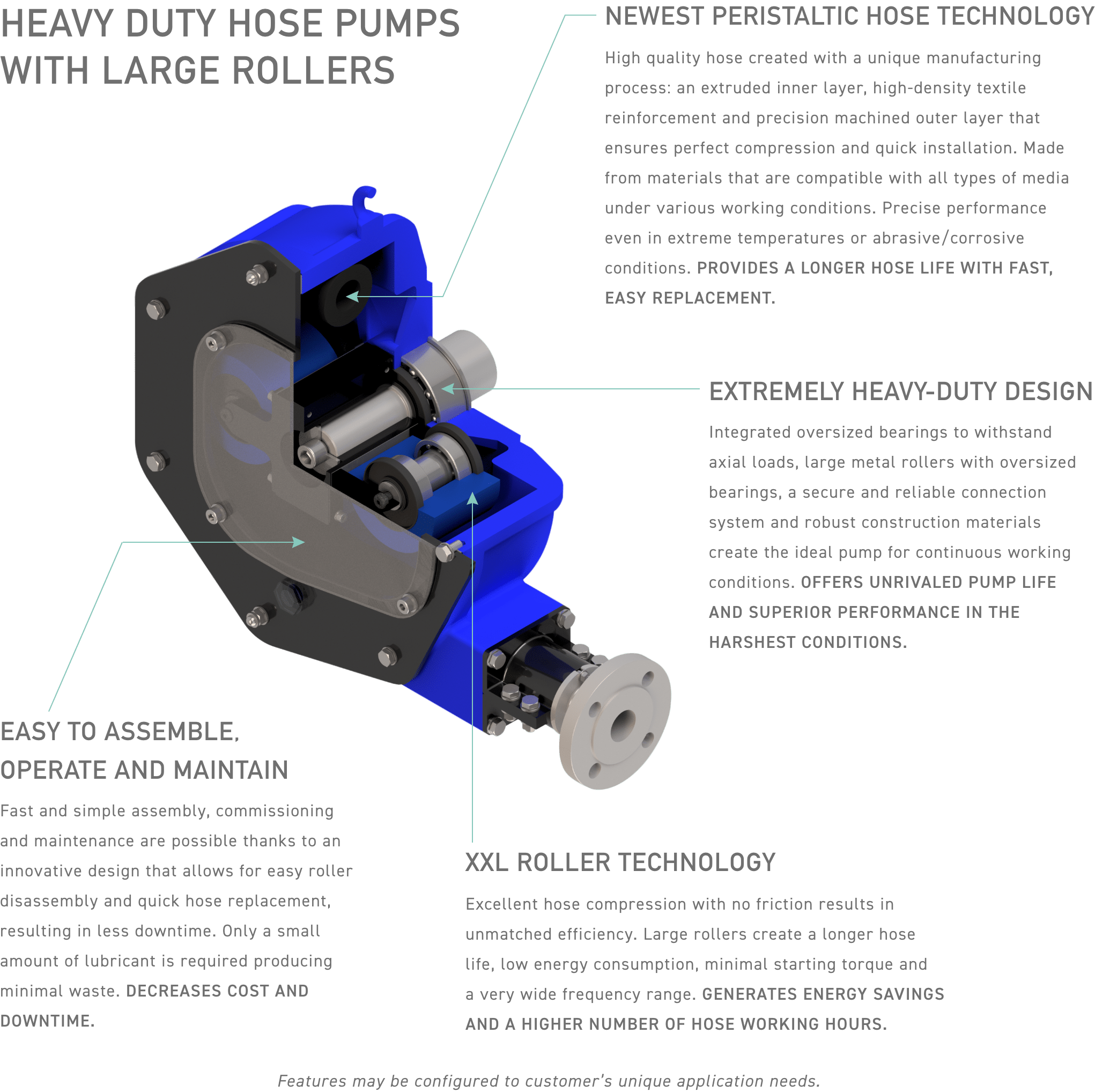

Newest peristaltic hose technology

High quality hose created with a unique manufacturing process: an extruded inner layer, high-density textile reinforcement and precision machined outer layer that ensures perfect compression and quick installation. Made from materials that are compatible with all types of media under various working conditions. Precise performance even in extreme temperatures or abrasive/ corrosive conditions. Provides a longer hose life with fast, easy replacement.

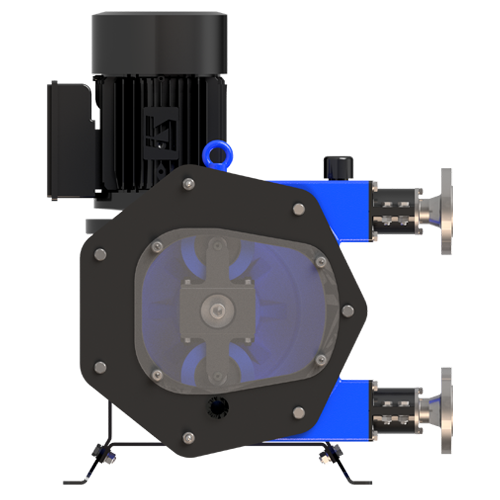

Extremely heavy-duty design

Integrated oversized bearings to withstand axial loads, large metal rollers with oversized bearings, a secure and reliable connection system and robust construction materials create the ideal pump for continuous working conditions. Offers unrivaled pump life and superior performance in the harshest conditions.

XXL roller technology

Excellent hose compression with no friction results in unmatched efficiency. Large rollers create a longer hose life, low energy consumption, minimal starting torque and a very wide frequency range. Generates energy savings and a higher number of hose working hours.

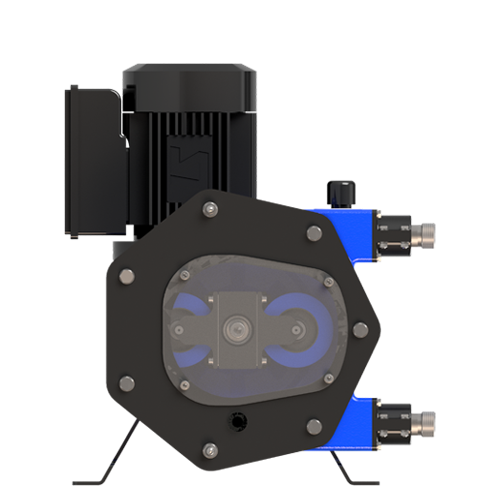

Easy to assemble, operate and maintain

Fast and simple assembly, commissioning and maintenance are possible thanks to an innovative design that allows for easy roller disassembly and quick hose replacement, resulting in less downtime. Only a small amount of lubricant is required producing minimal waste. Decreases cost and downtime.

Features may be configured to customer's unique application needs.