Your current roller pump may run at a higher RPM to achieve the same capacity as comparable Granzow pumps, decreasing pump and hose life.

Granzow pumps have wider diameter hoses that pump a higher capacity at a lower RPM. This creates a larger output, longer hose life and allows for a smaller pump to be used in some applications.

Your current pump likely uses rollers constructed from plastic and light alloy, which wear over time.

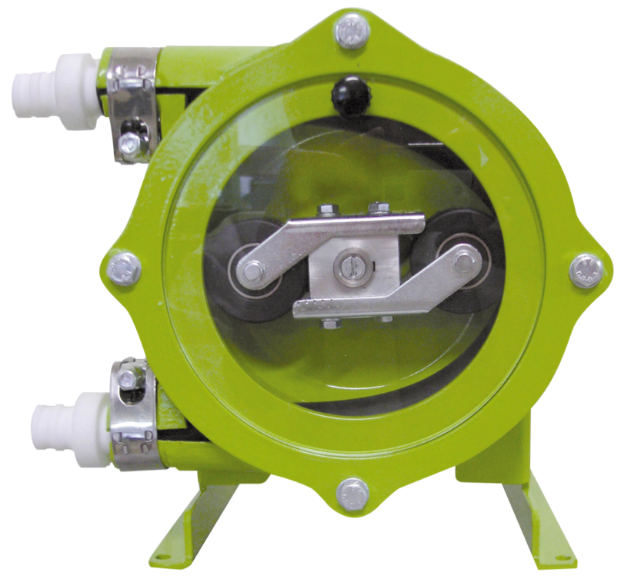

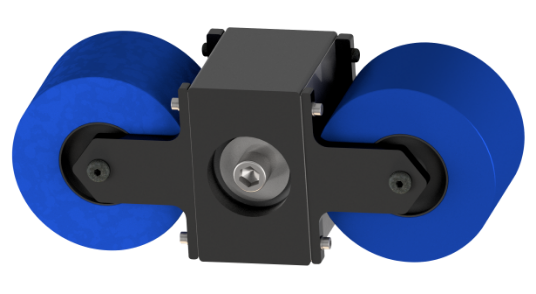

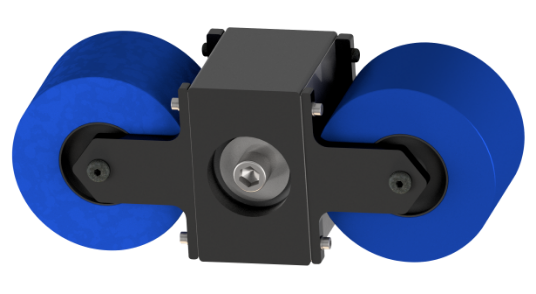

Granzow rollers are made from a hard anodized aluminum, increasing roller life and efficiency.

Your current roller pump likely uses third-party hoses, effecting consistency over time. They can also delaminate or need replacing after shorter periods of use than Granzow hoses.

Granzow's ground hoses have a tolerance of only +/- 0.2mm, allowing for total control of compression, longer hose life and savings on maintenance.

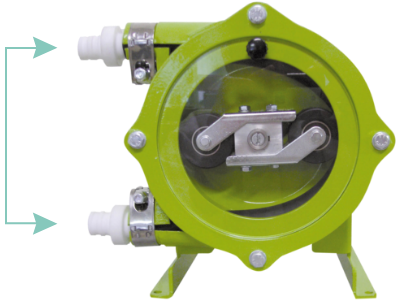

Your current hose pump likely uses plastic connections and hose clamps, sacrificing quality for lower short-term costs.

Granzow's clamping system is made from cast iron. This creates a strong, easy and safe connection with an extensive life.

Your current pump's hoses can be difficult to remove and replace. Roller pressure settings may be adjusted with every new hose due to variations in hose thickness, increasing maintenance time.

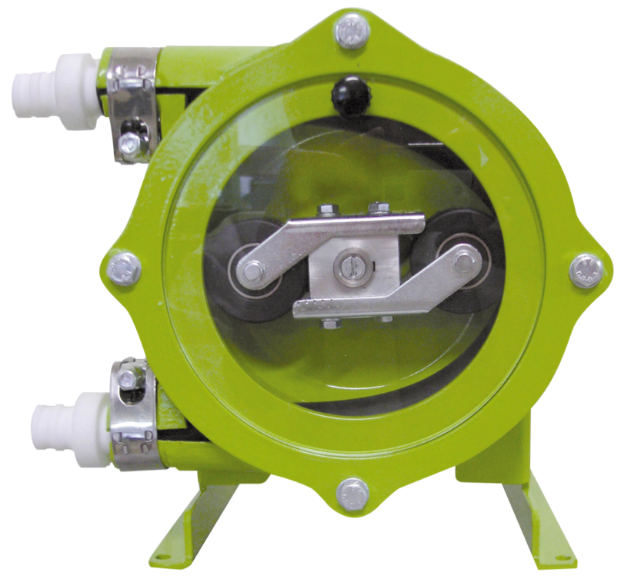

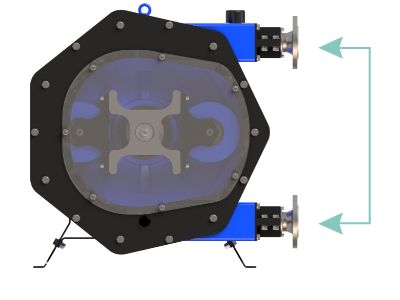

Granzow's unique design allows for easy roller disassembly and quick hose replacement, resulting in less downtime.

- Less friction

- Longer pump and hose life

- Less power consumption

- Lower starting torque

- Longer continuous use

- Wider frequency range

- Lower level of lubricant

- Easier assembly

- Simple hose replacement

Assembled in the USA and shipped from Granzow's exclusive, dedicated pump production facility in North Carolina. Hundreds of configurations are stocked and ready to ship within 2-3 days!

Assembled in the USA and shipped from Granzow's exclusive, dedicated pump production facility in North Carolina. Hundreds of configurations are stocked and ready to ship within 2-3 days!

Granzow heavy-duty peristaltic technology.

- Maximum resistance to abrasion.

- Unmatched suction capability.

- Indefinite dry running.

- No valves or mechanical seals.

- Gentle and reversible pumping.

- Full dosing control.

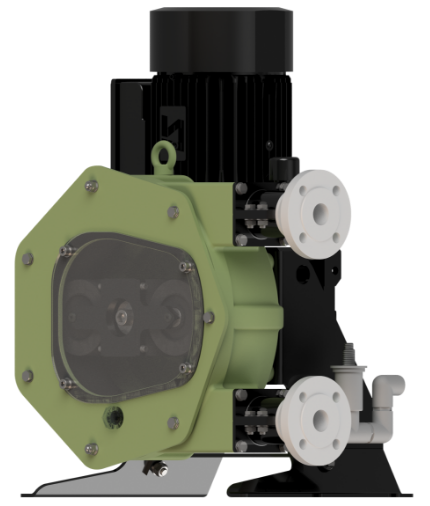

- Industrial, corrosion resistant and food versions.

- Dosing accuracy of ±1%.

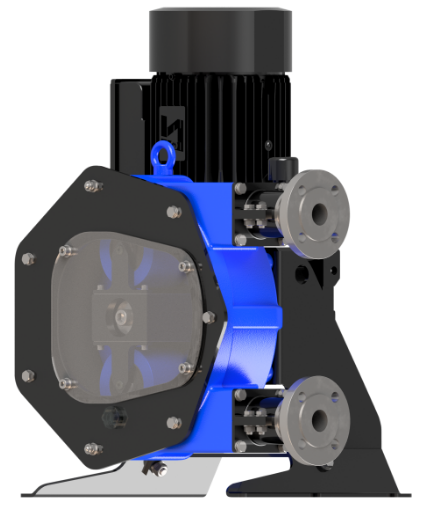

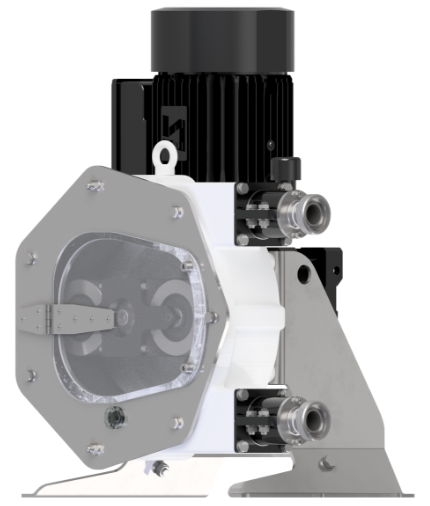

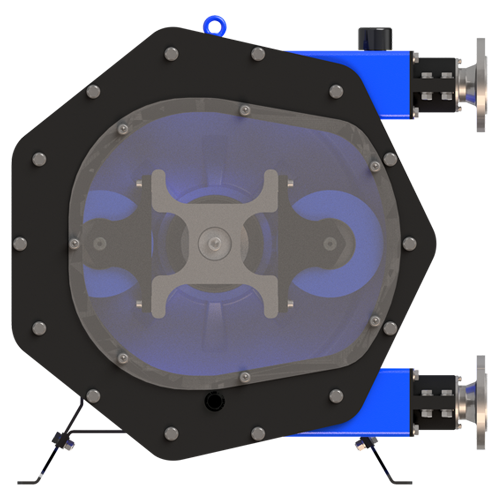

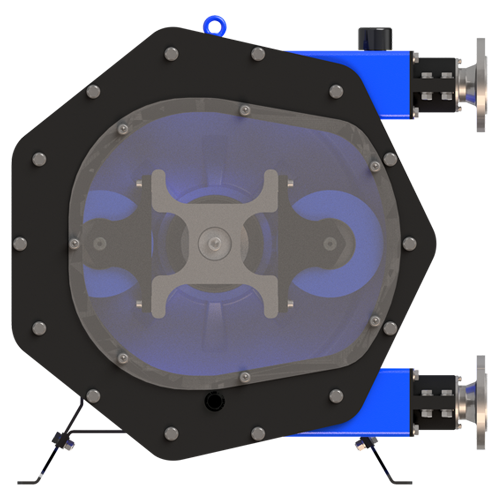

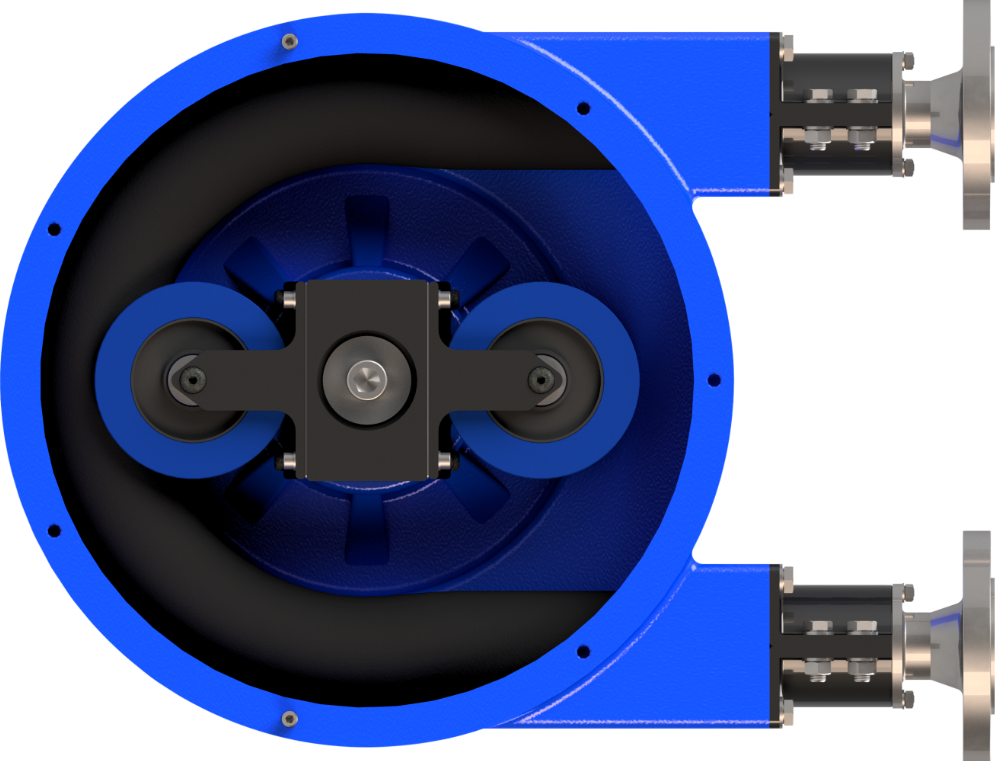

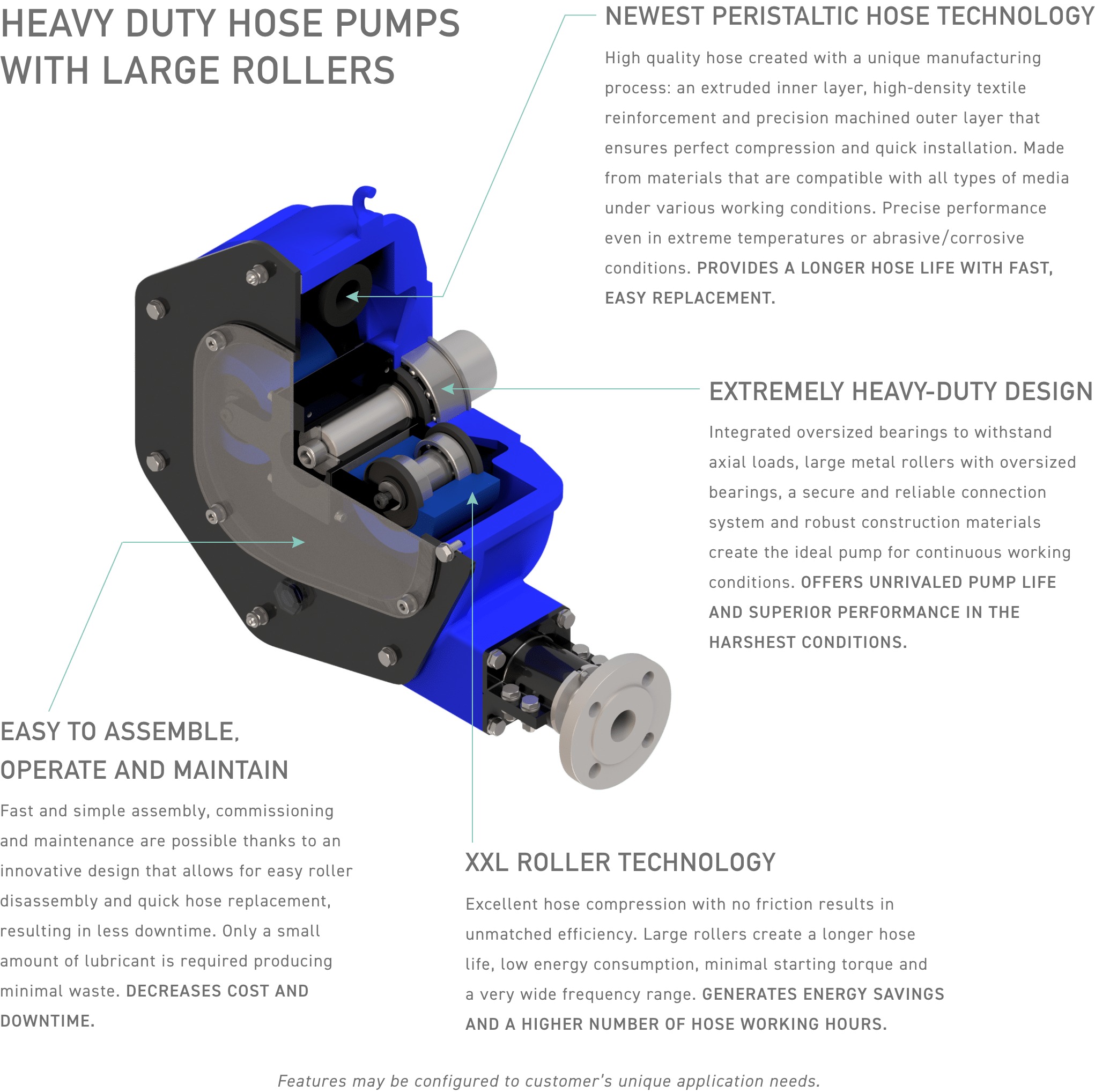

Heavy-duty hose pumps with large rollers

Newest peristaltic hose technology

High quality hose created with a unique manufacturing process: an extruded inner layer, high-density textile reinforcement and precision machined outer layer that ensures perfect compression and quick installation. Made from materials that are compatible with all types of media under various working conditions. Precise performance even in extreme temperatures or abrasive/corrosive conditions. Provides a longer hose life with fast, easy replacement.

Extremely heavy-duty design

Integrated oversized bearings to withstand axial loads, large metal rollers with oversized bearings, a secure and reliable connection system and robust construction materials create the ideal pump for continuous working conditions. Offers unrivaled pump life and superior performance in the harshest conditions.

Easy to assemble, operate and maintain

Fast and simple assembly, commissioning and maintenance. An innovative pump design allows for easy roller disassembly and quick hose replacement, resulting in less downtime. Maintenance-free pump with lubricated-for-life system requires only a small amount of lubricant, producing minimal waste. Decreases cost and downtime.

XXL roller technology

Excellent hose compression with no friction results in unmatched efficiency. Large rollers create a longer hose life, low energy consumption, minimal starting torque and a very wide frequency range. Generates energy savings and a higher number of hose working hours.

Industries

Versions

Select a version to learn more