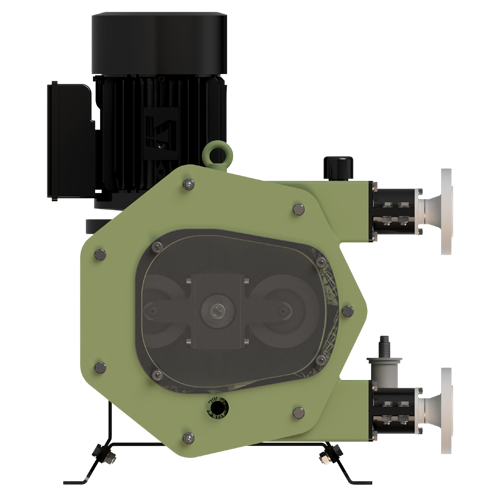

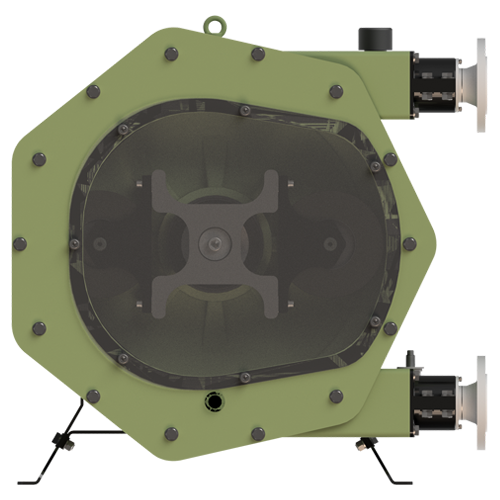

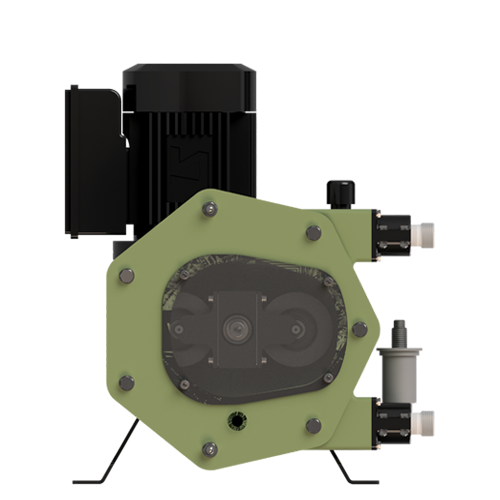

Granzow offers an extremely durable and anticorrosive chemical-version peristaltic pump that provides superior technical performance in demanding environments with corrosive and aggressive fluids. The pump includes a heavy-duty design, Tefzel® coated front cover and housing, polypropylene or PVDF connections, hose leakage sensor, drainage system, corrosion-resistant rollers, and newest hose technology in EPDM or Hypalon. Our chemical and abrasion resistant pumps are constructed using the newest peristaltic hose technology and premium materials to prevent leaks, reduce the need for replacement parts and minimize downtime.

Key Benefits

- Constructed with materials that are resistant to abrasion when transferring highly concentrated acids and other aggressive chemical solutions

- Precise dosing of abrasive slurries, flocculants or off-gassing liquids with ±1% accuracy

- Gentle, low-shear pumping to prevent damage to precious media

- Heavy duty design allows 24/7 continuous use

- Ability to pump gaseous products indefinitely

- Easy to assemble, operate and maintain

- Operates without damage if supply lines run dry

- Requires significantly less lubricant compared to shoe pumps

- Low ownership costs due to the pump's long life and easily changeable wear resistant hoses

Common Applications

- Pumping acids and other corrosive chemicals

- Dosing a variety of performance chemicals such as insecticides, bactericides, fungicides and herbicides

- Gently pumping difficult products that form gas during transfer, such as sodium hypochlorite

- Transferring and metering aluminum sulphate, catalytic agents, hydrocarbons, solvents, polymers, titanium dioxide and resin

- Transferring calcium tartrate and highly abrasive crystals

- Dosing fluids in chemical production

Perfect for dosing liquids, transferring highly corrosive media or gently pumping difficult products that form gas during transfer.

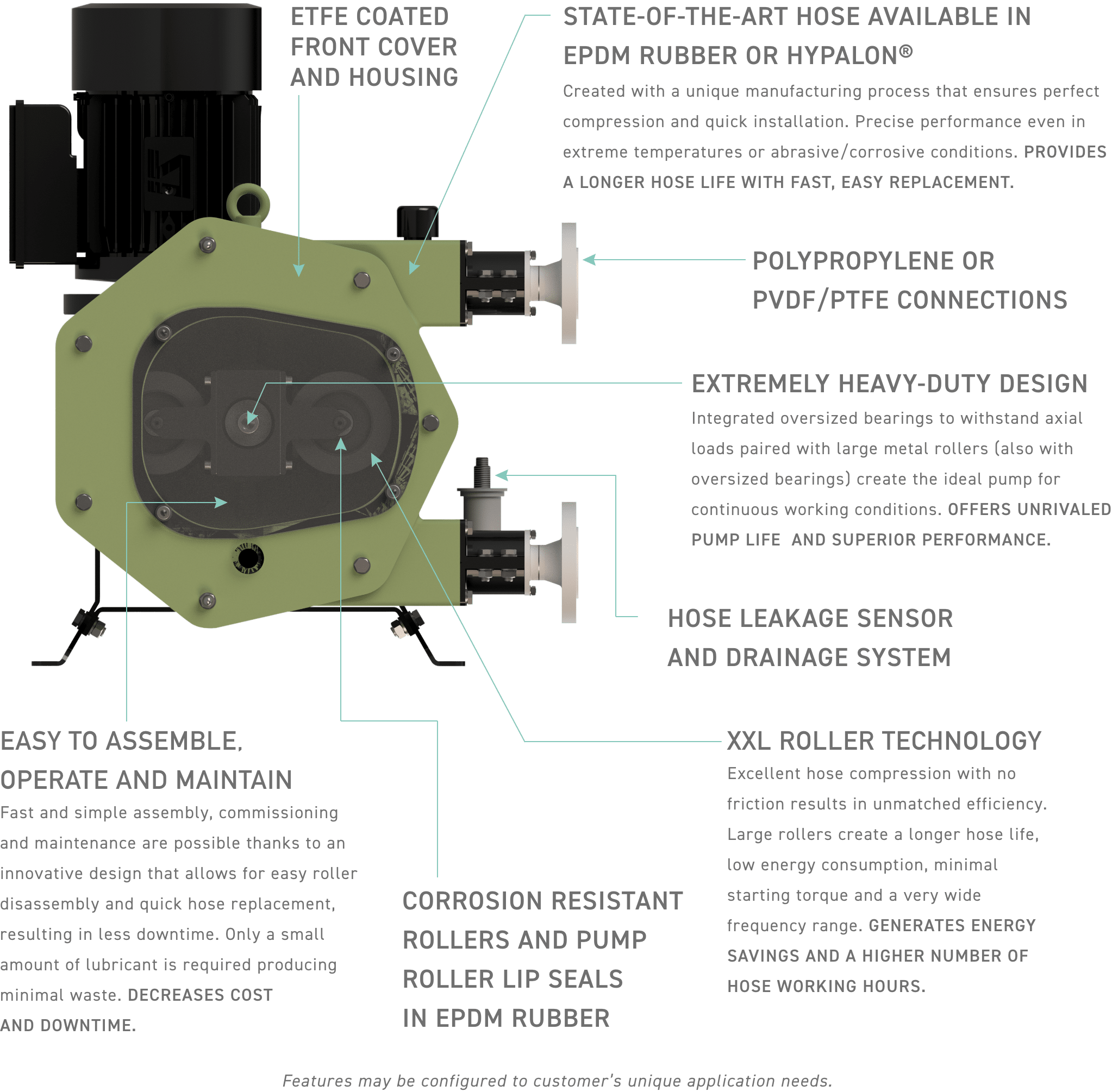

Tefzel (ETFE) coated front cover and housing

State-of-the-art hose available in EPDM or Hypalon

Created with a unique manufacturing process that ensures perfect compression and quick installation. Precise performance even in extreme temperatures or abrasive/ corrosive conditions. Provides a longer hose life with fast, easy replacement.

Polypropylene or PVDF connections

Extremely heavy-duty design

Integrated oversized bearings to withstand axial loads paired with large metal rollers (also with oversized bearings) create the ideal pump for continuous working conditions. Offers unrivaled pump life and superior performance.

Hose-leakage sensor and drainage system

XXL roller technology

Excellent hose compression with no friction results in unmatched efficiency. Large rollers create a longer hose life, low energy consumption, minimal starting torque and a very wide frequency range. Generates energy savings and a higher number of hose working hours.

Corrosion-resistant rollers and pump roller lip seals in EPDM

Easy to assemble, operate and maintain

Fast and simple assembly, commissioning and maintenance are possible thanks to an innovative design that allows for easy roller disassembly and quick hose replacement, resulting in less downtime. Only a small amount of lubricant is required producing minimal waste. Decreases cost and downtime.

Features may be configured to customer's unique application needs.